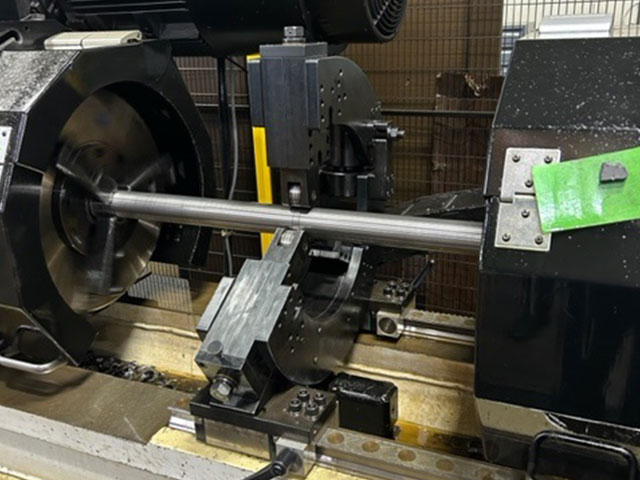

You are probably asking yourself what is the difference between gun drilling, deep hole drilling and boring. The answer is simple, in boring or deep hole drilling we use a bigger tool and drill a deeper hole.

Trepanning is used for coring out the inside of the material by returning a solid core to the customer but this process is slower. Customers usually only choose the trepanning option if it’s a high value material like Inconel or Copper.

Specifications

Diam of Holes:

2.00’’-9.50’’

Holding tolerances of:

.001’’ of drift per inch

Drilling Depth:

up to 240’’

Type of Holes:

Types of material:

Why Choose Midwest Precision Manufacturing?

Our business is built upon a single mission: to deliver world-class products and services combined with exceptional customer care. Our unwavering commitment to this goal is key to developing strong, long-term relationships in our industry. To stay ahead in a competitive market and offer innovative solutions, Midwest Precision Manufacturing continuously invests in advanced technology and equipment. We are dedicated to ensuring your complete satisfaction from start to finish. Whether your business is small or large, we are fully equipped to manage projects of any volume, and many of our solutions come with quick turnaround times. For more information about what we offer, please see the table below, or contact us directly.